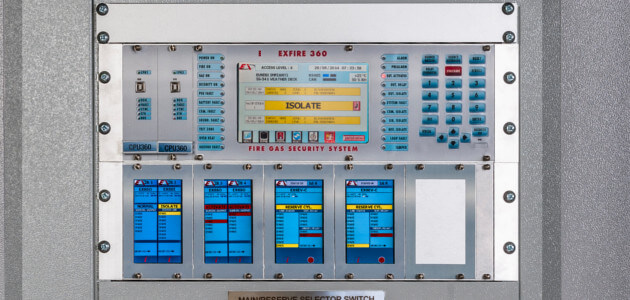

MINI EXFIRE360

MINI EXFIRE360 IMPLEMENTAZIONI DEI REQUISITI OPZIONALI 4.29-4.30 DELLA NORMA EN12094-1

IMPLEMENTAZIONI DEI REQUISITI OPZIONALI 4.29-4.30 DELLA NORMA EN12094-1 PENDING

LA NUOVA MINI EXFIRE360

in merito agli aspetti normativi, la centrale ottempera non solo ai requisiti cogenti delle normeEN 54-2, EN 54-4 (sistemi di rivelazione fire) ed EN 12094-1 (impianti di estinzione), EN 60079-29-1(sistemi di rivelazione Gas ATEX) ma è certificata per svolgere una serie di funzioni opzionali contemplate dalle medesime normative e comunemente richieste nei sistemi antincendio industriali. mini exfire360

Si consideri, a titolo esemplificativo, la disponibilità di un’interfaccia normalizzata di ingresso e uscita per la comunicazione bidirezionale della centrale con sistemi di terze parti, oppure il comando di sistemi di protezione antincendio, o, ancora, la gestione dei gruppi di spegnimento di riserva e la supervisione delle segnalazioni di pressione (alta/bassa) dei sistemi medesimi.

La centrale EXFIRE360 è stata dunque sviluppata implementando soluzioni tecnologiche mirate per rispondere ai requisiti delle norme EN54-2, EN54-4, EN12094-1, EN60079-29-1, GOST, prossimamente, UL864 e IEC61508 TUV, protocollo utilizzato HOCHIKI APOLLO.

NUOVA CONFIGURAZIONE DI SPEGNIMENTO EN12094-1 PER EXFIRE360

La presente sezione introduce le implementazioni che verranno eseguite sia sulla centrale EXFIRE360 che sulla sua versione compatta per rispondere ai requisiti dei punti 4.29 (rilascio degli agenti estinguenti per zone di scarica selezionate) e 4.30 (attivazione dei dispositivi di allarme con segnali diversi) della normativa EN12094-1.

Rispetto alla scheda EX6EV-C attualmente certificata per lo spegnimento, SV intende proporre una nuova configurazione in cui il ruolo dei singoli canali di ingresso/uscita non sia definito a priori ed in cui le logiche siano eseguite direttamente da EXCPU360.

Analizzando nel dettaglio le schede

Analizzando nel dettaglio le schede

Le schede impiegate per gestire questo sistema saranno 2 EX6EV, 2 EX6SO e 2 EX8SI (oppure una EXLOOP-E in aggiunta per la sola parte di rivelazione).

Analizzando nel dettaglio i singoli segnali, si avrà che:

La rivelazione sarà eseguita acquisendo almeno 2 segnali di tipo convenzionale per zona (scheda EX8SI o EX6EV) oppure attraverso dispositivi di tipo indirizzabile (scheda EXLOOP-E). La logica di attivazione delle solenoidi sarà definita nel programma di configurazione della centrale (SV Protection);

I pulsanti di scarica saranno acquisiti sotto un ingresso convenzionale (EX8SI o EX6EV). Il programma di configurazione della centrale sarà modificato affinchè per ogni canale di ingresso possa essere definita una funzionalità specifica (es. manual release, abort button, etc);

Lo stesso principio sarà utilizzato anche per tutti i restanti ingressi (pulsanti di interruzione e prolungamento emergenza, selettori modalità automatico/manuale, selettori main/reserve, pressostati di alta e bassa pressione, segnali generici di supervisione dell’impianto);

Per quanto riguarda le uscite, la scheda EX6EV rimarrà la scheda responsabile del controllo delle solenoidi di zona (valvole direzionali) e potrà attivare anche i dispositivi ottico/acustici di avvertimento pre-scarica e di scarica avvenuta (punto 4.30). La funzionalità delle singole uscite è definita nel programma di configurazione della centrale. sarà prevista una scheda EX6EV per ciascuna zona di scarica.

La scheda EX6SO

Le schede EX6SO

Le schede EX6SO si occuperanno, invece; del comando alle solenoidi dei banchi di bombole main/reserve comuni ad entrambi gli impianti di spegnimento; nonché, dell’attuazione di eventuali dispositivi di allarme aggiuntivi. La funzione delle singole uscite è definita attraverso SV Protection;

Per rispondere al requisito della norma secondo cui un guasto generico non deve influenzare più di una zona di scarica; i comandi verso le solenoidi comuni saranno ridondati (come nell’esempio sopra si avrà; quindi, bisogno di 8 uscite in totale, per questo si utilizzeranno 2 EX6SO);

Il controllo di dispositivi ausiliari quali blocco ventilazione, chiusura serrande, etc. sarà effettuato attraverso le uscite non supervisionate delle scheda EX6EV e la logica di intervento sarà liberamente programmabile dall’utente attraverso SV Protection;

Il controllo dello stato dell’impianto e delle logiche di attivazione verrà eseguito attraverso le unità di controllo EXCPU360, secondo le funzionalità definite nel programma di configurazione.

Ad esempio, l’inibizione della scarica in presenza di un guasto su un dispositivo di prolungamento emergenza verrà decisa valutando lo stato di tutti i device configurati come tipo HOLD nel Protection. In questo modo sarà possibile anche configurare più linee di ingresso o uscita con una medesima funzionalità;

Le segnalazioni circa lo stato della zona di scarica (attivata/rilascio/guasto/etc.) si visualizzano sul display MODLCD della scheda EX6EV relativa;

Attraverso i menu dello stesso display sarà inoltre possibile modificare le impostazioni (ritardo di scarica/tempo di inibizione ripristino/etc.) di ogni zona di spegnimento, nonché disabilitare (a livello di accesso 3) la scarica stessa.

CHASSIS REMOTO (CONCENTRATORE)

CHASSIS REMOTO (CONCENTRATORE)

L’esempio precedente è relativo ad una configurazione “completa”. Con lo stesso tipo di logica sarà in ogni caso possibile gestire anche impianti meno complessi; (ad esempio una sola zona con un pressostato di alta pressione; un pulsante di scarica ed una sola solenoide da pilotare).

A differenza della configurazione certificata in precedenza; bloccata sull’utilizzo di una scheda EX8SI e di una EX6EV adiacenti; il nuovo approccio permetterà di coprire i requisiti impiantistici e normativi con un’unica scheda (EX6EV); essa sarà espandibile con ulteriori schede di ingresso (EX8SI o EXLOOP-E) o uscita (EX6EV o EX6SO) a seconda delle caratteristiche del sistema.

CHASSIS REMOTO (CONCENTRATORE)

Il paragrafo 12.3.2 della EN 54-2 prevede la possibilità di installare la c.c.s. su più involucri; a condizione siano rispettati i requisiti di integrità dei supporti di trasmissione di cui al punto 12.5.3.

Gli chassis delle centrale EXFIRE360 potranno dunque essere installati in involucri separati rispetto alla centrale; precisando che tali contenitori saranno equivalenti a quelli della centrale EXFIRE360 in versione “mini”.

Tali concentratori saranno alimentati dall’apparecchiatura di alimentazione di cui al punto B) o; in alternativa, dall’unità di alimentazione della centrale EXFIRE360; a seconda dei requisitivi installativi.

Vieni a trovarci sul nostro sito web Sv sistemi di sicurezza, oppure contattaci per un preventivo al numero 035 657055!

inoltre se ti interessa qualche articolo del mondo fire & gas visita il nostro e-commerce Shop-fire.com e non esitare a contattaci e richiedere un preventivo!